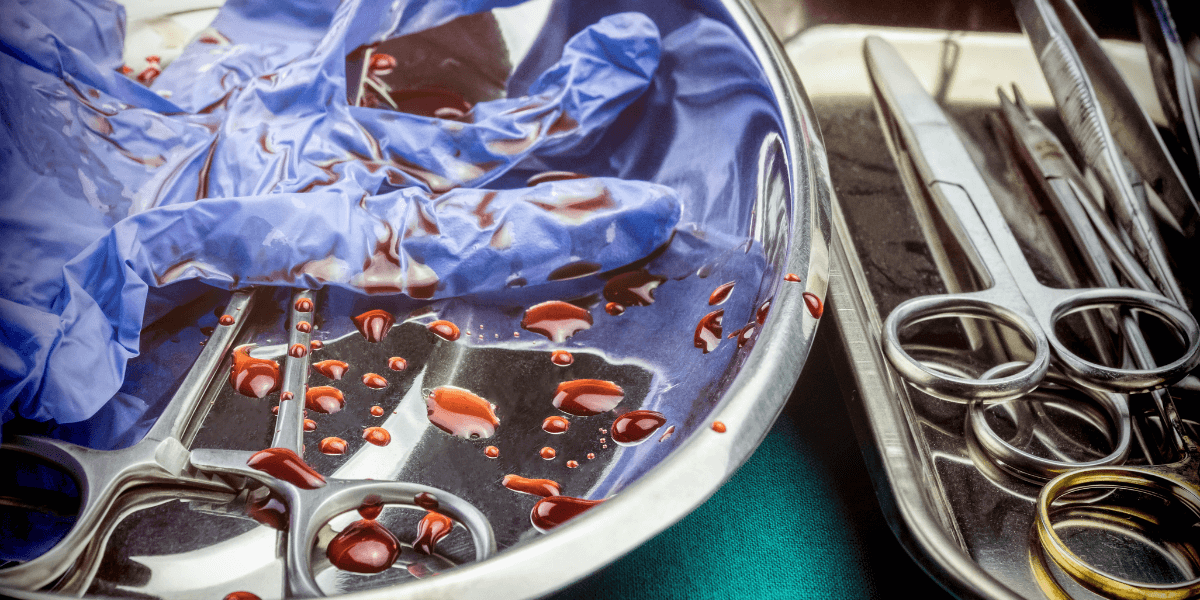

When it comes to high-precision medical tools, even the smallest oversight can have serious consequences. Instruments like scalpels, forceps, and other surgical tools are designed for accuracy and control, and keeping them sterile is vital. Contamination doesn’t just compromise patient safety; it can also reduce the lifespan of the instrument, cause corrosion, or affect performance.

The sterilisation of surgical instruments is a key part of infection control in every clinic and hospital across Australia. Following a consistent, evidence-based process guarantees that every procedure begins with tools that are clean, safe, and ready for use.

Why High-Precision Tools Need Extra Care?

High-precision medical instruments have delicate components like fine edges, intricate joints, and small hinges that require careful handling. These are not tools that can simply be wiped down or dipped in disinfectant. They need methodical, thorough cleaning and sterilisation steps to preserve their integrity.

When instruments are properly sterilised, their cutting ability, alignment, and performance remain consistent. Over time, this reduces the frequency of repairs and replacements, keeping overall costs lower for clinics and hospitals. Think of it as preventive maintenance that pays off in reliability and safety.

Step-By-Step Guide: How to Sterilise Scalpels and Forceps

Here's a detailed, step-by-step process for maintaining the sterility and longevity of your instruments. Each stage plays an important role in eliminating contaminants and preventing damage to your tools.

1. Immediate Pre-Cleaning

After a procedure, instruments should never sit with organic material on them. Start by rinsing them with cold, running water to remove visible blood and tissue. Avoid hot water as it can cause protein to coagulate, making it harder to clean later. Keep soiled instruments separate from clean ones during the entire process to prevent cross-contamination.

2. Manual Cleaning

Manual cleaning is the first real step in reprocessing. Use a neutral pH detergent and a soft-bristled, plastic cleaning brush. Scrub gently but thoroughly to remove any debris, paying attention to joints, serrations, and hinges. Always open hinged instruments during cleaning to allow detergent and water to reach all surfaces.

Avoid abrasive pads or harsh chemicals, which can scratch or corrode delicate metals. Rinse well once the instrument looks visibly clean to ensure no detergent residue remains.

- Ultrasonic Cleaning

For instruments with complex or hard-to-reach areas, ultrasonic cleaning is a must. Place tools in an ultrasonic cleaner filled with an enzymatic solution designed for medical use. Run the cycle for 10 to 20 minutes.

Ultrasonic vibrations create microscopic bubbles that collapse rapidly, dislodging even the tiniest particles from crevices and joints. This process achieves a level of cleaning that manual scrubbing alone can’t match, especially for cleaning high-precision medical tools. Once finished, rinse the instruments thoroughly under clean running water.

- Detailed Inspection

Once instruments are clean, inspect them under bright lighting or magnification. Look for residual stains, corrosion, or any damage to cutting edges. Scalpels, in particular, should have sharp, smooth blades without chips. Forceps and hinged tools should move freely without resistance or squeaks.

Instruments that are damaged should be repaired or replaced right away to avoid any complications during surgery. Regular inspection also helps identify wear before it becomes a problem.

5. Lubrication

Lubricating metal-to-metal joints is an often-overlooked step in surgical instrument maintenance tips. Use a water-soluble surgical lubricant, never an industrial oil. Apply it sparingly to hinges, box locks, and ratchets to keep instruments moving smoothly. Proper lubrication prevents rusting, binding, and wear caused by repeated autoclaving.

6. Wrapping and Preparation

Before sterilisation, arrange instruments in trays or wrap them in approved sterilisation pouches. Keep sharp or delicate items protected with tip guards. Make sure ratchets or locking mechanisms are left open so steam and heat can circulate freely.

If you use trays, avoid overcrowding them; steam needs space to move between instruments. Organise them logically so that they’re easy to handle after sterilisation.

7. Autoclaving

Autoclaving is the most reliable method for sterilising surgical instruments. It uses pressurised steam to kill all forms of microbial life. Follow manufacturer guidelines for temperature, pressure, and cycle time.

Common settings include 121°C for 30 minutes or 134°C for shorter exposure times, depending on the load. Always confirm that the autoclave is working correctly and record each cycle’s data for compliance purposes. Avoid overloading the autoclave; this prevents proper steam penetration.

8. Drying Cycle

Once the sterilisation cycle is complete, run a drying phase to remove any residual moisture. Open the autoclave door slightly to allow air circulation. Do not handle instruments immediately after the cycle. They’ll still be hot and susceptible to recontamination if touched too soon. When completely dry, check the integrity of the packaging and confirm that sterilisation indicators have changed colour.

Searching for specialised surgical or podiatry instruments? Browse MediTools Pty Ltd’s collection today!

Maintenance Tips for Forceps and Hinged Instruments

Forceps, hemostats, and needle holders require extra attention because of their complex joints. Clean and sterilise them while open, and never lock ratchets during sterilisation. Locked instruments prevent steam from reaching internal surfaces, which can leave them contaminated and may even cause cracking.

Inspect the serrations regularly to make sure they align perfectly. Poorly aligned jaws can damage delicate tissue or sutures. If alignment issues appear, have the instrument serviced rather than forcing it into use.

Storage and Long-Term Care

Once instruments are dry and sterile, proper storage is essential. Place sterilised packs in a clean, dust-free, temperature-controlled cabinet. Keep them off the floor and away from sinks or chemicals. Avoid stacking heavy trays on top of lighter ones, as this can compromise wrapping.

Organising instruments by type and date helps maintain rotation and guarantees older sets are used first. If a sterile pack is torn, wet, or shows any sign of compromise, it should be reprocessed immediately.

Common Mistakes to Avoid

It’s easy to make small errors that have big consequences. Avoid:

- Locking hinged instruments before sterilisation.

- Skipping ultrasonic cleaning for complex tools.

- Using household cleaners or industrial oils.

- Storing damp or warm instruments after sterilisation.

Consistency is key. Each step contributes to the long-term performance and safety of your instruments.

Conclusion

Every successful surgical procedure starts with clean, sharp, and sterile instruments. Following these sterilisation steps guarantees that scalpels, forceps, and other high-precision tools stay reliable, functional, and safe for use. A disciplined cleaning and sterilisation routine isn’t just about compliance, but it’s about protecting patients and extending the lifespan of your valuable equipment.

If you’re looking for high-quality medical instruments in Australia, contact MediTools Pty Ltd. Our expert team can help you source, maintain, and care for surgical, dental, and veterinary tools built for accuracy and durability!

Disclaimer

The content provided here on the sterilization, cleaning, and reprocessing of surgical and medical instruments is strictly for informational and educational purposes only. This information is not a substitute for professional training, certification, or the manufacturer's official Instructions for Use (IFU). Sterilization is a critical, complex process that demands strict adherence to regulatory standards; improper technique can cause serious harm, including patient infection. All healthcare personnel must follow their facility's established protocols and the specific IFU for every instrument and piece of equipment. By using this blog, you agree that the author/owner holds no liability for any damages or consequences resulting from the application or misuse of this information.